Article from RailFan.net

“Sleepy” radishes on the move from Florida to Ohio get wide-awake service from Southern Railway. They have to, in order to reach grocers’ produce bins still bright red, crisp and plump. And to make it possible, the radishes “take a nap” en route in an inert nitrogen atmosphere inside refrigerated trailers.

George Weasel, who owns Tem-Cole, Inc., one of the nation’s biggest radish producers, relies on Southern’s fast rail service to help transport tons of freshly harvested radishes from the firm’s Florida farm to its packing plant in McClure, Ohio. .

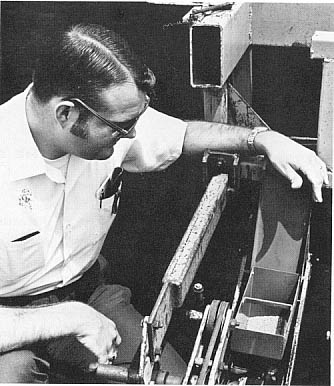

Jarrell Standridge, Southern’s sales representative in West Palm Beach, Fla., inspects the radish seeds used by Tem-Cole.

Jarrell Standridge, Southern’s sales representative in West Palm Beach, Fla., inspects the radish seeds used by Tem-Cole.

Radishes can deteriorate quickly after harvesting unless they are moved rapidly and efficiently in a temperature controlled environment to packing plants. The answer? Refrigerated trailers in a combined highway and rail movement.

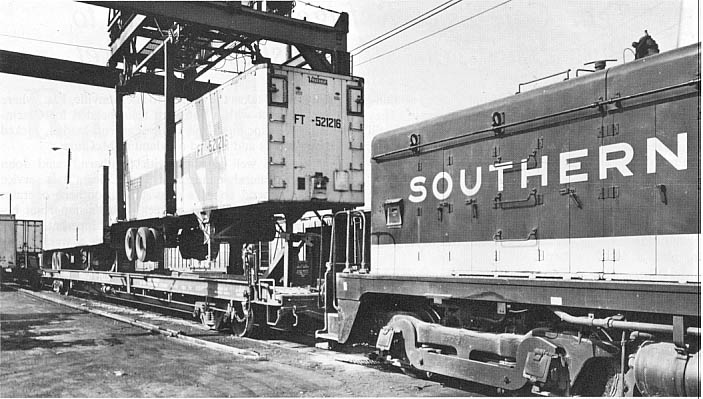

Loaded with radishes at Tem-Cole’s Belle Glade, Fla. farm site, the trailers speed by rail and road to reach the firm’s packing plant in McClure, Ohio. To eliminate unnecessary handling or delay, Southern works closely with the Florida East Coast Railway Company (FEC) and Tem-Cole’s contract carrier, H&L Trucking Company. FEC takes the trailers to Jacksonville, Fla., where they connect with a Southern train headed for Cincinnati. At Cincinnati the trailers are off-loaded, picked up by trucks and hauled overland to McClure.

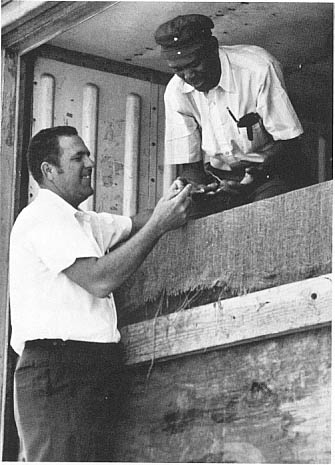

Bill Bennion (left), Southern’s district sales manager in West Palm Beach, Fla., and Leonard Henderson, Tem-Cole’s facility foreman at the pre-cooler in Belle Glade, Fla., examine some freshly harvested radishes. Mr. Henderson is responsible for cooling each trailer-load of radishes before it is shipped to the’ packing plant in McClure, Ohio.

Bill Bennion (left), Southern’s district sales manager in West Palm Beach, Fla., and Leonard Henderson, Tem-Cole’s facility foreman at the pre-cooler in Belle Glade, Fla., examine some freshly harvested radishes. Mr. Henderson is responsible for cooling each trailer-load of radishes before it is shipped to the’ packing plant in McClure, Ohio.

“We are well satisfied with Southern,” said John Fryman, general manager of Tem-Cole. “It is service we can depend on-its consistent. Southern operates 24 hours a day, 7 days a week. That’s important because radishes must be harvested and shipped at just the right time, even if the right time is on a weekend or holiday.”

Now claiming half of the radish market in the United States, Tem-Cole attributes its success to temperature and atmospheric control and innovations in planting, harvesting, transporting and packaging. George Weasel and his employees have designed most of the equipment they use in the field and at the packing plant.

To keep a just-harvested freshness, the temperature of radishes must stay around 37 degrees all the way from field to market. Pre-cooling procedures in Florida, the use of the refrigerated trailers in transit and continued cooling when the radishes reach Ohio all help accomplish this.

Movement of radishes begins at the 750-acre farm near Belle Glade where six men plant and harvest a 30-acre block of radishes almost every day from late October through late May. Each block yields about six crops during the growing season. During the summer months Tem-Cole switches the growing operation to 650 acres in Michigan.

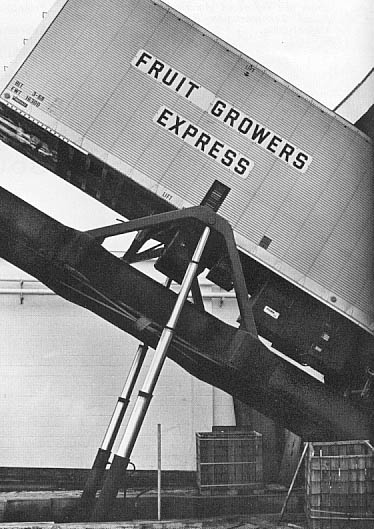

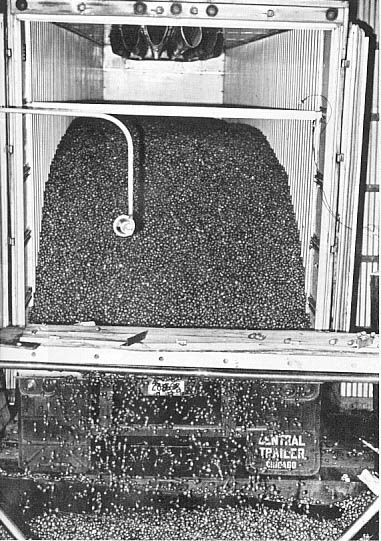

Each trailer dumps its 41,000 pounds of radishes into a special bin at the packing plant in McClure, Ohio.

Each trailer dumps its 41,000 pounds of radishes into a special bin at the packing plant in McClure, Ohio.

A special machine designed by Mr. Weasel, plants 28 rows at a time. One man can plant 14 miles of radishes in about ten minutes. Then the radishes take about 28 days to grow from seed to mature vegetable.

Harvesting is done by two machines also designed by Tem-Cole. These machines each pick 14 rows at a time, clipping the top off and dropping the radish into a bulk hopper. The tops are put back into the soil as mulch.

The harvested radishes are run through an initial wash to remove field dirt. Then they are loaded into the piggyback trailers, each holding 41,000 pounds of radishes.

The radishes are then put into pallet boxes and held in special 33-degree rooms until they are packaged and sent to market.

The trailers go to the FEC rail-highway loading ramp in Belle Glade where the pre-cooling process begins. First, Tem-Cole cycles cold water through the radishes to bring their temperature down to about 37 degrees. Then nitrogen is pressured into the trailers to replace the oxygen, arresting any further development of the radishes and keeping them in a freshly harvested condition for the long journey to market.

Within four hours after leaving the field, the radishes are processed and the trailers loaded onto rail cars. FEC ships the trailers to Jacksonville where Southern picks them up for the trip to Cincinnati. “We put them on a first class, high-speed train that reaches Cincinnati in about 30 hours,” said Bill Bennion, Southern’s district sales manager in West Palm Beach.

Within four hours after leaving the field, the radishes are processed and the trailers loaded onto rail cars. FEC ships the trailers to Jacksonville where Southern picks them up for the trip to Cincinnati. “We put them on a first class, high-speed train that reaches Cincinnati in about 30 hours,” said Bill Bennion, Southern’s district sales manager in West Palm Beach.

In Cincinnati, H&L Trucking Company picks up the trailers and delivers them to the packing plant in McClure, about four hours away. There Tem-Cole dumps the radishes out of the trailers, puts them in loose pallet boxes, and stores them in holding rooms where they stay at 33 degrees for about three days.

“We generally lose about 15 per cent of our radishes during inspection,” Mr. Fryman said. “We don’t want any cracked, split or discolored radishes to leave our plant.”

At Southern’s Rail-Highway piggyback ramp in Cincinnati, the Fruit Growers Express trailers are off-loaded and picked up by tractors for the trip to McClure.

After the inspection process, Tem-Cole once again dunks the radishes in ice water to keep them chilled, and puts them into 6-ounce transparent packages boxed in 30-package cartons for delivery to market. One more cooling process. is Used to get rid of any heat generated by the cartons.

Next year both Tem-Cole and Southern will be a little busier. Mr. Weasel plans to move his farm site to 1,000 acres recently purchased near Belle Glade. He will be planting and shipping more radishes than ever.

“We also plan to expand our packing facilities in either Florida or Ohio next year,” Mr. Fryman said. ” And Tem-Cole is also looking at the European market.”

George Weasel and his employees constantly look for better ways to grow radishes. And Southern Railway constantly looks for better ways to meet his transportation needs.